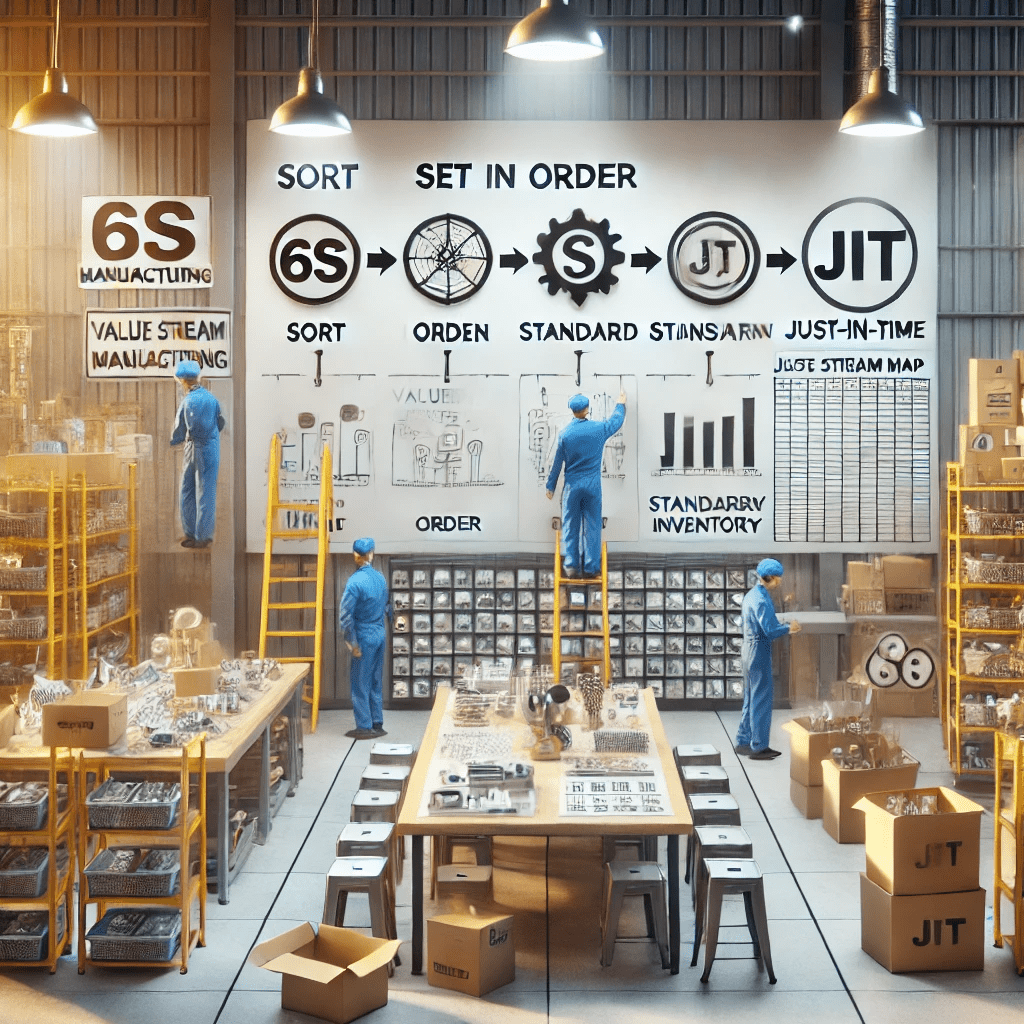

Optimize your processes, eliminate waste, and enhance operational efficiency with our Lean Manufacturing Solutions.

Our team brings years of experience in Lean methodologies like 6S, VSM, and JIT.

2. Customized SolutionsTailored strategies to meet your unique business and production needs.

3. Efficiency FocusReduce waste, improve workflows, and boost overall productivity.

4. Continuous ImprovementDrive lasting organizational change with measurable results.

Transform Your Manufacturing Process. Achieve Lean Excellence Today!