KOMAL ENTERPRISES

Introduction

Introduction

KOMAL ENTERPRISES was established in the year 2011. Our young and dynamic team of highly experienced and dedicated professionals are ready to deliver the complete solutions for CNC machines. We have 15+ years of Machine tool experience. We are providing the complete solutions of CNC Machines.

Our Products

Our Products

- Ball Screw

- Spindle

- Precision Lock Nut

- Disc Spring

- Geometry Mandrills

- Lubrication Unit

- Level Bottle

- Allignment Gauges

- Spindle Clamprite Gauge

- Hydraulic Turret and Their Spares

- Rotary Union for Coolant

- Linear Blocks and Rails

- Ring Gauge

- Plug Gauge

- MT Taper

- Garbid Drill Bit

- Chamfering Cutter

- T Slot Cutter

Ball Screw

A high-precision screw assembly that converts rotary motion into precise linear motion with minimal backlash, ensuring accuracy and repeatability. Ball screws employ recirculating balls between the screw shaft and nut to dramatically reduce friction and wear under heavy loads. They are widely used in CNC machines, robotics, and high-precision industrial applications where smooth, reliable positioning is critical.

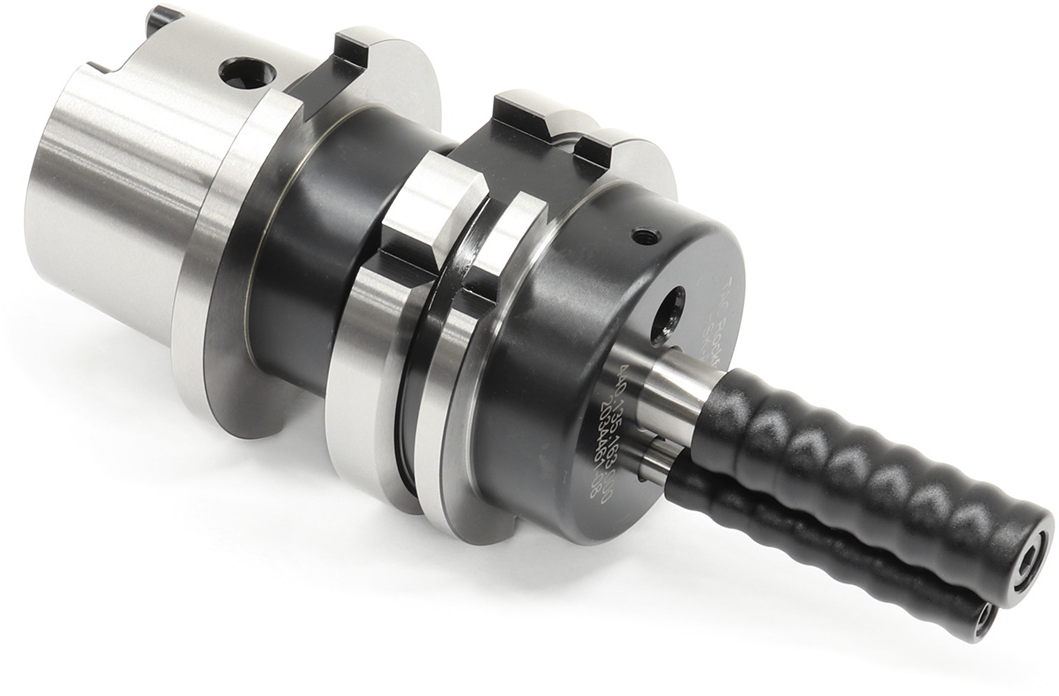

Spindle

The spindle is the core rotating shaft assembly in machining centers and lathes that holds, drives, and precisely controls the cutting tool. It integrates bearings, drive motors, and tool-holding interfaces to deliver high RPMs and torque under variable loads. A well-engineered spindle minimizes vibration and thermal growth, enhancing surface finish and extending tool life.

Precision Lock Nut

A precision lock nut is specially machined to preload the ball screw assembly, eliminating axial play and maintaining consistent positioning accuracy. It uses adjustable preload settings to balance rigidity and friction, allowing fine-tuning for each application’s load requirements. These nuts are essential in precision machinery, where even micron-level backlash can impact performance.

Disc Spring

Disc springs, also known as Belleville washers, are conical spring washers that provide high force in a compact package. Their stacked configurations enable adjustable load and deflection characteristics, making them ideal for preload, vibration isolation, and energy absorption applications. Common uses include clutches, brakes, and bolted joint tensioning in heavy-duty machinery.

Geometry Mandrills

Geometry mandrills are hardened mandrels used for calibrating and checking internal bore geometry and alignment with high precision. They ensure concentricity and surface finish conformity in critical components, preventing misalignment in assembled parts. Typically made from high-grade tool steel, they resist wear and maintain tight tolerances over repeated use.

Lubrication Unit

A lubrication unit integrates a pump, reservoir, and distribution network to automatically supply precise amounts of lubricant to bearings and sliding surfaces. It reduces maintenance downtime by ensuring consistent lubrication intervals and volumes. Common in CNC machines and automated lines, these units protect components from wear and prevent overheating under continuous operation.

Level Bottle

Allignment Gauges

Spindle Clamprite Gauge

Hydraulic Turret and Their Spares

Rotary Union for Coolant

Linear Blocks and Rails

Ring Gauge

Plug Gauge

MT Taper

Garbid Drill Bit

Chamfering Cutter