6. Frequently Asked Questions

▶>

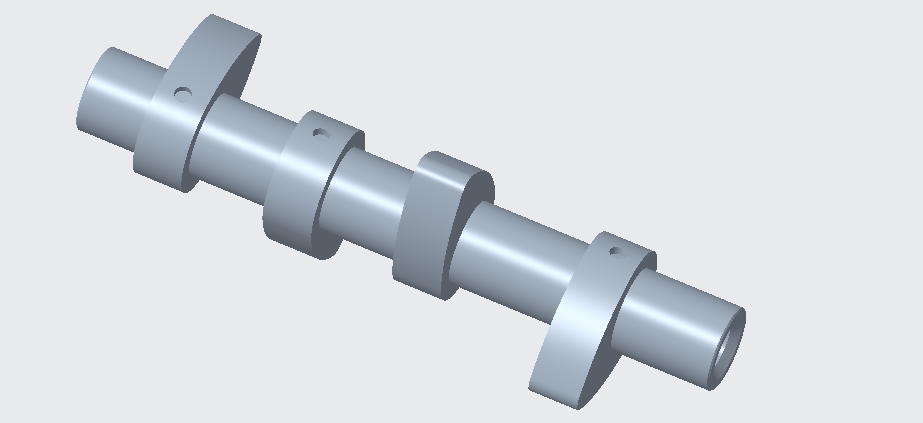

A camshaft is a crucial component in an internal combustion engine. Its primary function is to control the timing and movement of the engine's intake and exhaust valves. The camshaft rotates and the cams (lobes) push against the valve lifters or rocker arms to open the valves at precise times during the engine cycle.

>

The shape and timing of the cams on the camshaft determine how effectively an engine can breathe, which directly affects the engine's power and efficiency. Modifications to the camshaft profile can increase the engine's power output by optimizing the timing of valve opening and closing for better air and fuel mixture and exhaust gas expulsion.

>

Camshafts can be classified based on their construction material (e.g., cast iron, steel), method of fabrication (e.g., cast, forged, billet), or their placement in the engine (e.g., overhead camshaft (OHC) vs. cam-in-block). Each type has different characteristics suitable for specific engine designs and performance requirements.

>

High-performance camshafts are designed with aggressive cam profiles that open the valves further and for longer durations. This allows more air and fuel into the combustion chamber and lets exhaust gases exit more completely, which can significantly increase power output. However, they may also impact the smoothness of engine operation and fuel efficiency.

>

Camshafts can sometimes be repaired if they are not severely damaged. Techniques like welding, grinding, and polishing are used to restore the camshaft's shape and surface integrity. However, if the damage is extensive, replacement might be more cost-effective and reliable.

>

Common signs that a camshaft may need to be replaced include abnormal engine noise, reduced engine power, increased fuel consumption, and problematic idle. These can result from worn or damaged cam lobes and bearings which affect the timing and efficiency of valve operations.

>

Wear and tear: Over time, the cam lobes can wear down, reducing their effectiveness in opening valves.

Lobe damage: Impact or excessive wear can cause lobes to flatten or become misshapen.

Bearing failure: Bearings that support the camshaft can fail, leading to camshaft seizure or misalignment.

Lobe damage: Impact or excessive wear can cause lobes to flatten or become misshapen.

Bearing failure: Bearings that support the camshaft can fail, leading to camshaft seizure or misalignment.

>

Camshafts do not have a regular replacement interval, but their condition should be assessed during major engine overhauls or if there are symptoms of failure. Regular maintenance and oil changes can help extend the life of a camshaft by ensuring proper lubrication.

>

Single Overhead Camshaft (SOHC) engines have one camshaft per cylinder head, controlling both intake and exhaust valves.

Double Overhead Camshaft (DOHC) engines have two camshafts per cylinder head, typically one controlling intake valves and the other controlling exhaust valves. This allows for better airflow at high engine speeds, improving performance.

Double Overhead Camshaft (DOHC) engines have two camshafts per cylinder head, typically one controlling intake valves and the other controlling exhaust valves. This allows for better airflow at high engine speeds, improving performance.

>

Camshaft timing affects how efficiently an engine burns its air-fuel mixture, which directly impacts emissions. Advanced variable valve timing technologies allow the engine to adjust the timing of valve opening and closing to optimize combustion under different conditions, thereby reducing harmful emissions.